نيوبات الليثيوم

| |

| |

| الأسماء | |

|---|---|

| أسماء أخرى

Lithium niobium oxide, lithium niobium trioxide

| |

| المُعرِّفات | |

| رقم CAS | |

3D model (JSmol)

|

|

| ChemSpider | |

| ECHA InfoCard | 100.031.583 |

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| |

| |

| الخصائص | |

| الصيغة الجزيئية | LiNbO3 |

| كتلة مولية | 147.846 g/mol |

| المظهر | colorless solid |

| الكثافة | 4.30 g/cm3[2] |

| نقطة الانصهار | |

| قابلية الذوبان في الماء | None |

| الفجوة الحزمية | 3.77 eV [1] |

| معامل الانكسار (nD) | no 2.3007, ne 2.2116[3] |

| البنية | |

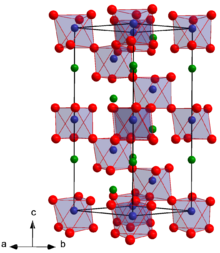

| البنية البلورية | Trigonal, hR30 |

| الزمرة الفراغية | R3c, No. 161 |

| ثابت العقد | a = 0.51501 nm, b = 0.51501 nm, c = 0.54952 nm |

| ثابت العقد | α = 62.057°, β = 62.057°, γ = 60° |

| المخاطر | |

| الجرعة أو التركيز القاتل (LD, LC): | |

LD50 (الجرعة الوسطى)

|

8 g/kg (oral, rat)[4] |

ما لم يُذكر غير ذلك، البيانات المعطاة للمواد في حالاتهم العيارية (عند 25 °س [77 °ف]، 100 kPa). | |

| مراجع الجدول | |

Lithium niobate (LiNbO

3) is a synthetic salt consisting of niobium, lithium, and oxygen. Its single crystals are an important material for optical waveguides, mobile phones, piezoelectric sensors, optical modulators and various other linear and non-linear optical applications.[5] Lithium niobate is sometimes referred to by the brand name linobate.[6]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Properties

Lithium niobate is a colorless solid, and it is insoluble in water. It has a trigonal crystal system, which lacks inversion symmetry and displays ferroelectricity, the Pockels effect, the piezoelectric effect, photoelasticity and nonlinear optical polarizability. Lithium niobate has negative uniaxial birefringence which depends slightly on the stoichiometry of the crystal and on temperature. It is transparent for wavelengths between 350 and 5200 nanometers.

Lithium niobate can be doped with magnesium oxide, which increases its resistance to optical damage (also known as photorefractive damage). Other available dopants are iron, zinc, hafnium, copper, gadolinium, erbium, yttrium, manganese and boron.

Growth

Single crystals of lithium niobate can be grown using the Czochralski process.[7]

After a crystal is grown, it is sliced into wafers of different orientation. Common orientations are Z-cut, X-cut, Y-cut, and cuts with rotated angles of the previous axes.[8]

Thin films

Thin-film lithium niobate (e.g. for optical wave guides) can be transferred to or grown on sapphire and other substrates, using the smart cut (ion slicing) process[9][10] or MOCVD process.[11] The technology is known as lithium niobate on insulator (LNOI).[12]

Nanoparticles

Nanoparticles of lithium niobate and niobium pentoxide can be produced at low temperature.[13] The complete protocol implies a LiH induced reduction of NbCl5 followed by in situ spontaneous oxidation into low-valence niobium nano-oxides. These niobium oxides are exposed to air atmosphere resulting in pure Nb2O5. Finally, the stable Nb2O5 is converted into lithium niobate LiNbO3 nanoparticles during the controlled hydrolysis of the LiH excess.[14] Spherical nanoparticles of lithium niobate with a diameter of approximately 10 nm can be prepared by impregnating a mesoporous silica matrix with a mixture of an aqueous solution of LiNO3 and NH4NbO(C2O4)2 followed by 10 min heating in an infrared furnace.[15]

Applications

Lithium niobate is used extensively in the telecommunications market, e.g. in mobile telephones and optical modulators.[16] Due to its large electro-mechanical coupling, it is the material of choice for surface acoustic wave devices. For some uses it can be replaced by lithium tantalate, LiTaO

3. Other uses are in laser frequency doubling, nonlinear optics, Pockels cells, optical parametric oscillators, Q-switching devices for lasers, other acousto-optic devices, optical switches for gigahertz frequencies, etc. It is an excellent material for manufacture of optical waveguides. It's also used in the making of optical spatial low-pass (anti-aliasing) filters.

In the past few years lithium niobate is finding applications as a kind of electrostatic tweezers, an approach known as optoelectronic tweezers as the effect requires light excitation to take place.[17][18] This effect allows for fine manipulation of micrometer-scale particles with high flexibility since the tweezing action is constrained to the illuminated area. The effect is based on the very high electric fields generated during light exposure (1–100 kV/cm) within the illuminated spot. These intense fields are also finding applications in biophysics and biotechnology, as they can influence living organisms in a variety of ways.[19] For example, iron-doped lithium niobate excited with visible light has been shown to produce cell death in tumoral cell cultures.[20]

Periodically poled lithium niobate (PPLN)

Periodically poled lithium niobate (PPLN) is a domain-engineered lithium niobate crystal, used mainly for achieving quasi-phase-matching in nonlinear optics. The ferroelectric domains point alternatively to the +c and the −c direction, with a period of typically between 5 and 35 µm. The shorter periods of this range are used for second-harmonic generation, while the longer ones for optical parametric oscillation. Periodic poling can be achieved by electrical poling with periodically structured electrode. Controlled heating of the crystal can be used to fine-tune phase matching in the medium due to a slight variation of the dispersion with temperature.

Periodic poling uses the largest value of lithium niobate's nonlinear tensor, d33 = 27 pm/V. Quasi-phase-matching gives maximum efficiencies that are 2/π (64%) of the full d33, about 17 pm/V.[21]

Other materials used for periodic poling are wide-band-gap inorganic crystals like KTP (resulting in periodically poled KTP, PPKTP), lithium tantalate, and some organic materials.

The periodic-poling technique can also be used to form surface nanostructures.[22][23]

However, due to its low photorefractive damage threshold, PPLN only finds limited applications, namely, at very low power levels. MgO-doped lithium niobate is fabricated by periodically poled method. Periodically poled MgO-doped lithium niobate (PPMgOLN) therefore expands the application to medium power level.

Sellmeier equations

The Sellmeier equations for the extraordinary index are used to find the poling period and approximate temperature for quasi-phase-matching. Jundt[24] gives

valid from 20 to 250 °C for wavelengths from 0.4 to 5 micrometers, whereas for longer wavelengths,[25]

which is valid for T = 25 to 180 °C, for wavelengths λ between 2.8 and 4.8 micrometers.

In these equations f = (T − 24.5)(T + 570.82), λ is in micrometers, and T is in °C.

More generally for ordinary and extraordinary index for MgO-doped LiNbO

3:

with:

| Parameters | 5% MgO-doped CLN | 1% MgO-doped SLN | |

|---|---|---|---|

| ne | no | ne | |

| a1 | 5.756 | 5.653 | 5.078 |

| a2 | 0.0983 | 0.1185 | 0.0964 |

| a3 | 0.2020 | 0.2091 | 0.2065 |

| a4 | 189.32 | 89.61 | 61.16 |

| a5 | 12.52 | 10.85 | 10.55 |

| a6 | 1.32×10−2 | 1.97×10−2 | 1.59×10−2 |

| b1 | 2.860×10−6 | 7.941×10−7 | 4.677×10−7 |

| b2 | 4.700×10−8 | 3.134×10−8 | 7.822×10−8 |

| b3 | 6.113×10−8 | −4.641×10−9 | −2.653×10−8 |

| b4 | 1.516×10−4 | −2.188×10−6 | 1.096×10−4 |

for congruent LiNbO

3 (CLN) and stochiometric LiNbO

3 (SLN).[26]

انظر أيضاً

References

- ^ Zanatta, A.R. (August 2022). "The optical bandgap of lithium niobate (LiNbO3) and its dependence with temperature". Results Phys. 39: 105736–3pp. doi:10.1016/j.rinp.2022.105736. S2CID 249688492.

- ^ Haynes, p. 4.70

- ^ Haynes, p. 10.250

- ^ "ChemIDplus – 12031-63-9 – PSVBHJWAIYBPRO-UHFFFAOYSA-N – Lithium niobate – Similar structures search, synonyms, formulas, resource links, and other chemical information".

- ^ Weis, R. S.; Gaylord, T. K. (1985). "Lithium Niobate: Summary of Physical Properties and Crystal Structure". Applied Physics A: Materials Science & Processing. 37 (4): 191–203. Bibcode:1985ApPhA..37..191W. doi:10.1007/BF00614817. S2CID 97851423.

- ^ Staebler, D.L.; Amodei, J.J. (1972). "Thermally fixed holograms in LiNbO3". Ferroelectrics. 3 (1): 107–113. Bibcode:1972Fer.....3..107S. doi:10.1080/00150197208235297. S2CID 51674085., seen in Yeh, Pochi; Gu, Claire, eds. (1995). Landmark Papers On Photorefractive Nonlinear Optics. World Scientific. p. 182. ISBN 9789814502979.

- ^ Volk, Tatyana; Wohlecke, Manfred (2008). Lithium Niobate: Defects, Photorefraction and Ferroelectric Switching. Springer. pp. 1–9. doi:10.1007/978-3-540-70766-0. ISBN 978-3-540-70765-3.

- ^ Wong, K. K. (2002). Properties of Lithium Niobate. London, United Kingdom: INSPEC. p. 8. ISBN 0-85296-799-3.

- ^ Levy, M.; Osgood, R. M.; Liu, R.; Cross, L. E.; Cargill, G. S.; Kumar, A.; Bakhru, H. (1998-10-19). "Fabrication of single-crystal lithium niobate films by crystal ion slicing". Applied Physics Letters (in الإنجليزية). 73 (16): 2293–2295. Bibcode:1998ApPhL..73.2293L. doi:10.1063/1.121801. ISSN 0003-6951.

- ^ Lu, H.; Sadani, B.; Courjal, N.; Ulliac, G.; Smith, N.; Stenger, V.; Collet, M.; Baida, F. I.; Bernal, M. P. (2012). "Enhanced electro-optical lithium niobate photonic crystal wire waveguide on a smart-cut thin film". Optics Express. 20 (3): 2974–2981. doi:10.1364/oe.20.002974. PMID 22330535. Retrieved 2022-07-08.

- ^ Feigelson, R. S. (1996). "Epitaxial growth of lithium niobate thin films by the solid source MOCVD method". Journal of Crystal Growth. 166 (1–4): 1–16. Bibcode:1996JCrGr.166....1F. doi:10.1016/0022-0248(95)00570-6.

- ^ Hu, Hui; Yang, Jin; Gui, Li; Sohler, Wolfgang (2012). "Lithium niobate-on-insulator (LNOI): Status and perspectives" (PDF). Silicon Photonics and Photonic Integrated Circuits III. Vol. 8431. pp. 84311D. doi:10.1117/12.922401. S2CID 120452519.

- ^ Grange, R.; Choi, J.W.; Hsieh, C.L.; Pu, Y.; Magrez, A.; Smajda, R.; Forro, L.; Psaltis, D. (2009). "Lithium niobate nanowires: synthesis, optical properties and manipulation". Applied Physics Letters. 95 (14): 143105. Bibcode:2009ApPhL..95n3105G. doi:10.1063/1.3236777. Archived from the original on 2016-05-14.

- ^ Aufray M, Menuel S, Fort Y, Eschbach J, Rouxel D, Vincent B (2009). "New Synthesis of Nanosized Niobium Oxides and Lithium Niobate Particles and Their Characterization by XPS Analysis". Journal of Nanoscience and Nanotechnology. 9 (8): 4780–4789. CiteSeerX 10.1.1.465.1919. doi:10.1166/jnn.2009.1087. PMID 19928149.

- ^ Grigas, A; Kaskel, S (2011). "Synthesis of LiNbO3 nanoparticles in a mesoporous matrix". Beilstein Journal of Nanotechnology. 2: 28–33. doi:10.3762/bjnano.2.3. PMC 3045940. PMID 21977412.

- ^ Toney, James (2015). Lithium Niobate Photonics. Artech House. ISBN 978-1-60807-923-0.

- ^ Carrascosa, M.; García-Cabañes, A.; Jubera, M.; Ramiro, J. B.; Agulló-López, F. (2015). "LiNbO3: A photovoltaic substrate for massive parallel manipulation and patterning of nano-objects". Applied Physics Reviews. AIP Publishing. 2 (4): 040605. Bibcode:2015ApPRv...2d0605C. doi:10.1063/1.4929374. hdl:10486/669584. ISSN 1931-9401.

- ^ García-Cabañes, Angel; Blázquez-Castro, Alfonso; Arizmendi, Luis; Agulló-López, Fernando; Carrascosa, Mercedes (2018-01-30). "Recent Achievements on Photovoltaic Optoelectronic Tweezers Based on Lithium Niobate". Crystals. MDPI AG. 8 (2): 65. doi:10.3390/cryst8020065. hdl:10486/681685. ISSN 2073-4352.

- ^ Blázquez-Castro, A.; García-Cabañes, A.; Carrascosa, M. (2018). "Biological applications of ferroelectric materials". Applied Physics Reviews. AIP Publishing. 5 (4): 041101. arXiv:2109.00429. Bibcode:2018ApPRv...5d1101B. doi:10.1063/1.5044472. ISSN 1931-9401. S2CID 139511670.

- ^ Blázquez-Castro, Alfonso; Stockert, Juan C.; López-Arias, Begoña; Juarranz, Angeles; Agulló-López, Fernando; García-Cabañes, Angel; Carrascosa, Mercedes (2011). "Tumour cell death induced by the bulk photovoltaic effect of LiNbO3:Fe under visible light irradiation". Photochemical & Photobiological Sciences. Springer Science and Business Media LLC. 10 (6): 956–963. doi:10.1039/c0pp00336k. ISSN 1474-905X. PMID 21336376.

- ^ Meyn, J.-P.; Laue, C.; Knappe, R.; Wallenstein, R.; Fejer, M. M. (2001). "Fabrication of periodically poled lithium tantalate for UV generation with diode lasers". Applied Physics B. 73 (2): 111–114. Bibcode:2001ApPhB..73..111M. doi:10.1007/s003400100623. S2CID 119763435.

- ^ Grilli, Simonetta; Ferraro, Pietro; De Natale, Paolo; Tiribilli, Bruno; Vassalli, Massimo (2005). "Surface nanoscale periodic structures in congruent lithium niobate by domain reversal patterning and differential etching". Applied Physics Letters. 87 (23): 233106. Bibcode:2005ApPhL..87w3106G. doi:10.1063/1.2137877.

- ^ Ferraro, P.; Grilli, S. (2006). "Modulating the thickness of the resist pattern for controlling size and depth of submicron reversed domains in lithium niobate". Applied Physics Letters. 89 (13): 133111. Bibcode:2006ApPhL..89m3111F. doi:10.1063/1.2357928.

- ^ Jundt, Dieter H. (1997). "Temperature-dependent Sellmeier equation for the index of refraction in congruent lithium niobate". Optics Letters. 22 (20): 1553–1555. Bibcode:1997OptL...22.1553J. doi:10.1364/OL.22.001553. PMID 18188296.

- ^ Deng, L. H.; Gao, X. M.; Cao, Z. S.; Chen, W. D.; Yuan, Y.Q.; Zhang, W. J.; Gong, Z. B. (2006). "Improvement to Sellmeier equation for periodically poled LiNbO3 crystal using mid-infrared difference-frequency generation". Optics Communications. 268 (1): 110–114. Bibcode:2006OptCo.268..110D. doi:10.1016/j.optcom.2006.06.082.

- ^ Gayer, O.; Sacks, Z.; Galun, E.; Arie, A. (2008). "Temperature and wavelength dependent refractive index equations for MgO-doped congruent and stoichiometric LiNbO3". Appl. Phys. B. 91 (2): 343–348. Bibcode:2008ApPhB..91..343G. doi:10.1007/s00340-008-2998-2. S2CID 195290628.

Cited sources

- Haynes, William M., ed. (2016). CRC Handbook of Chemistry and Physics (97th ed.). CRC Press. ISBN 9781498754293.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .